|

Gongda Jixie Machine Co.,Ltd

|

pop can filling machine

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

we have more than 600 staffs and got ISO9001-2000 quality system and CE certificate.

Cans filling and sealing machine is introduced from Swiss advanced technology, after digestion and absorption, self-designed and manufactured, it can be widely used in cans beer, beverages, mineral water filling and sealing. The machine has changed the traditional two divided machine model, adopting two in one together way to make structure tight, operation stable, attractive appearance.

1cans enter section2filling section3 exhaust section4blank line section

This machine is mainly used for filling and capping pop cans carbonated beverage with holding bottle bottom conveyor method to make the whole line conveying stable.

It adopts counter pressure principle with high-precision mechanical valve, high speed filling, high precision liquid level, no cans no filling. It has guiding devices with filling valve mouth to ensure the stability maximum from cans in and out filling machine. The filling tank adopts automatic lifting support method with worm gear box, to meet the different height of the cans.

In filling cylinder has liquid level switch to ensure into liquid stability.

This machine first use low voltage CO2 blowing in cans air before opening the valve to ensure the purity of CO2 in cans.

It adopts counter pressure principle with high-precision mechanical valve, high speed filling, high precision liquid level, no cans no filling. It has guiding devices with filling valve mouth to ensure the stability maximum from cans in and out filling machine. The filling tank adopts automatic lifting support method with worm gear box, to meet the different height of the cans.

In filling cylinder has liquid level switch to ensure into liquid stability.

This machine first use low voltage CO2 blowing in cans air before opening the valve to ensure the purity of CO2 in cans.

The main drive gear and gear box with a combination of open-drive, high efficiency, low noise, smooth operation; frequency conversion stepless speed regulation, industrial computer control with the PLC, filling machine and sealing machine adopts universal joint connection, to ensure two machine synchronization.

Sealing rollers adopt high hardness alloy steel hardened, sealing curve with the optical curve grinding precision manufacture, to make sure the sealing quality. With have can will drop the cap, without can will no cap to drop control system, to ensure the normal operation of the machine.

Leading cans system can be changed according to different type can.

The whole machine adopts concentrating lubricate system to make equipment maintenance more convenient and fast.

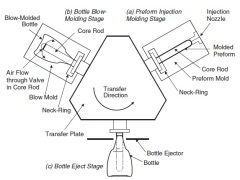

Equipment working position picture:

The filling machine is mainly made of enter can position, filling position, exhaust position, blank line position. The details picture as follow:

Sealing rollers adopt high hardness alloy steel hardened, sealing curve with the optical curve grinding precision manufacture, to make sure the sealing quality. With have can will drop the cap, without can will no cap to drop control system, to ensure the normal operation of the machine.

Leading cans system can be changed according to different type can.

The whole machine adopts concentrating lubricate system to make equipment maintenance more convenient and fast.

Equipment working position picture:

The filling machine is mainly made of enter can position, filling position, exhaust position, blank line position. The details picture as follow:

1cans enter section2filling section3 exhaust section4blank line section

1 | Application | soda water, juice, tea, energy drinks, beer, carbonated drinks, beer, etc. |

2 | Suitable for | aluminum can, pop can and PET can |

3 | Filling method | Filling system: gravity or isobaric filling |

4 | Production capacity | 2,000CPH – 20,000CPH (330ml) |

Related Search

Can Filling Machine

Filling Machine

Can Making Machine

Capsule Filling Machine

Liquid Filling Machine

Drink Filling Machine

More>>